| Sign In | Join Free | My gastesters.com |

|

- Home

- Products

- About Us

- Quality Control

- Contact Us

- Get Quotations

| Sign In | Join Free | My gastesters.com |

|

Brand Name : Customer's Requirments

Model Number : Custom

Certification : ISO2008, TUV, , ROHS

Place of Origin : Guangdong, China(mainland)

MOQ : 1 PC

Price : Negotiable

Payment Terms : L/C, T/T, Western Union, Paypal, D/P, D/A, MoneyGram

Supply Ability : 3000 pcs per month

Delivery Time : 13-33 working days after receiving deposit

Packaging Details : Packed in a bubble bag individually, then separated by a foam, finally put in standard export carton packing, or OEM packing.

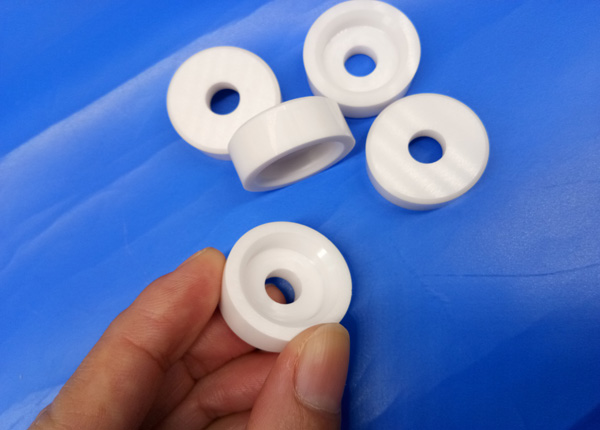

Product name : Zirconia Ceramic Washer

Material : Zirconia / alumina ceramic

Density : 3.9g/cm3 / >6.0g/cm3

HV Hardness : 1300 - 1650 Mpa

Dielectric Strength : 9.5 9.8 26

Compressive Strength@Room Temperature : 2000 - 2200 Mpa

Flexural Strength @ Room Temperature : Mpa / 280 ( 95 al3o2 ), 310 ( 99 al3o2 ), 950 ( zirconia )

Max application temperature : W / m * k / 18 - 25 ( 95 al3o2 ), 26 - 30 ( 99 al3o2 ), 2.0 - 2.2 ( zro2 )

Color and Size : Black; Customized

Application : Ceramic washer industrial parts

High HV Hardness Zirconia Ceramic Parts Fire Resistance Zirconia Ceramic Washer

Product Description

Manufacturing of zirconia ceramics using high-purity zirconia materials, insulation at room temperature, and high temperature has electrical conductivity and other excellent properties.High temperature resistance Melting point is 2715 ℃,1200mpa hardness.

Ceramic material composition:

· TTZ: Magnesia partially stabilized Zirconia (ZrO2) · YTZP: Yttria partially stabilized Zirconia (ZrO2) · ZDY: Yttria fully stabilized Zirconia (ZrO2)

The main features of the zirconia ceramic washer

1.High density: over 6 g/cm3, which makes it the densest body of the ceramic products

2.High hardness: over 9 on Mohs scale, diamond being 10, with a satin-smooth surface finish

3.High toughness: over 1200 MPa, approx. 4 times in comparison with 95% alumina

4. Excellent wear resistance, it's much better than aluminum oxide ceramics with longer life cycle

5. Low thermal conductivity: less than 3 W/m.k at ambient temperature, so it's an ideal thermal material

6. Good chemical and corrosion resistance, it's equivalent to above 99% alumina

The specification of ceramic washer

| Material option | Zirconia (ZrO2), Alumina(Al2O3), Silicon carbide(SiO2), Silicon nitride(Si3N4) |

| Forming methods | Dry pressed, Ceramic injection molding, Hot pressed, ISO pressed |

| Specification | OD can be from 1 to 50mm, length can be from 10mm to 800mm |

| Precision processing | CNC machining, Precision grinding, Polishing, Lapping, |

| Tolerance | The tolerance of OD and ID can be 0.001mm, the tolerance of length can be 0.001mm |

| Key parameters | Roughness to be 0.02mm, Parallelism to be 0.001mm |

| Surface quality | Free of cracks, foreign contamination, mirror surface better than Ra0.1 |

They deliver 10 times longer working life than metal rods.

Properties Sheet:

| Item | Unit | Zirconia /ZrO2 |

| Heat resistant | ºC | 2200 |

| Bulk density | g/cm3 | 6.05 |

| Water absorption | % | 0 |

| Flexural strength | Mpa | 1000 |

| Hardness vickers | Gpa | 89 |

| Elastic modulus | Gpa | 200 |

| Linear expansion | (20-500 ºC) 10 -6 / ºC | 10 |

| Thermal conductivity | w/(m.k) | 2 |

Detailed Images

Related Products

Alumina porous ceramic plate

Zirconia ceramic guide rod

View More Products

Packaging and Shipping

Zirconia Ceramic Washer will be packed in a bubble bag individually, then separated by a foam, finally put in standard export carton packing, or OEM packing.

Shipped by Air ( DHL, TNT, UPS, Fedex, EMS ), or Sea transportation.

Company information

Who Are We?

Mingrui has professional OEM experience in manufacturing industrial ceramic parts for so many

years. We can make the products according to your drawings, custom the size, thickness and other parameters.

.

What Do We Do?

We have very advanced technologies in the production of zirconia and alumina ceramic nozzle, rod, ring, tube, shaft, plate, sleeve, valve, plunger, bearing, and semiconductive ceramics etc.. They are applicable to Electrical, Appliance, Oil & Gas, Energy & Power, Food & Medical, Agriculture, Aerospace,

even other high-end fields.

.

Our products with some certificates, such as , CE, TUV, etc..

Factory Show

Production Process Show

One-stop production, from the raw material powder to final product.

Delivery:

Custom OEM will be shipped within 15 days after determining the parameters

The samples will be shipped within 3 days

Quick Delivery Via Fedex,DHL,UPS,TNT Etc.

Support customer to designate shipping company

For more informations (the price,delivery time,moq etc)about the ceramic plates, please contact us or email:admin@cerampart.com

CEO: Admin deng

Dongguan Mingrui Ceramic Tech. Co. Ltd.

Add: No.21 Chuangxing Rd., 2nd Industrial Zone of Shangsha,

Chang'an town, Dongguan city, Guangdong, China 523867

Email: admin@cerampart.com

FAQ

1. Monthly Capacity: 50,000-60,000 pcs;

2. Material: OEM or as per your suggestion;

3. Lead time: about 7-20 days, pls confirm the quantities required;

4. Incoterm: FOB, CFR, CIF;

5. Delivery Cost: It is determinated by the destination port;

6. Payment Term: PayPal; T/T; L/C.

7. Shipment: by sea, by air, by courier, by post, etc.

|

|

High HV Hardness Zirconia Ceramic Parts Fire Resistance Zirconia Ceramic Washer Images |